Logic Diagram Instrumentation 14++ Images Result

Logic Diagram Instrumentation. It includes all piping, instruments, valves and equipment that the system consist of. A) instrument line symbols b) instrument functional diagramming symbols c) mathematical function block symbols

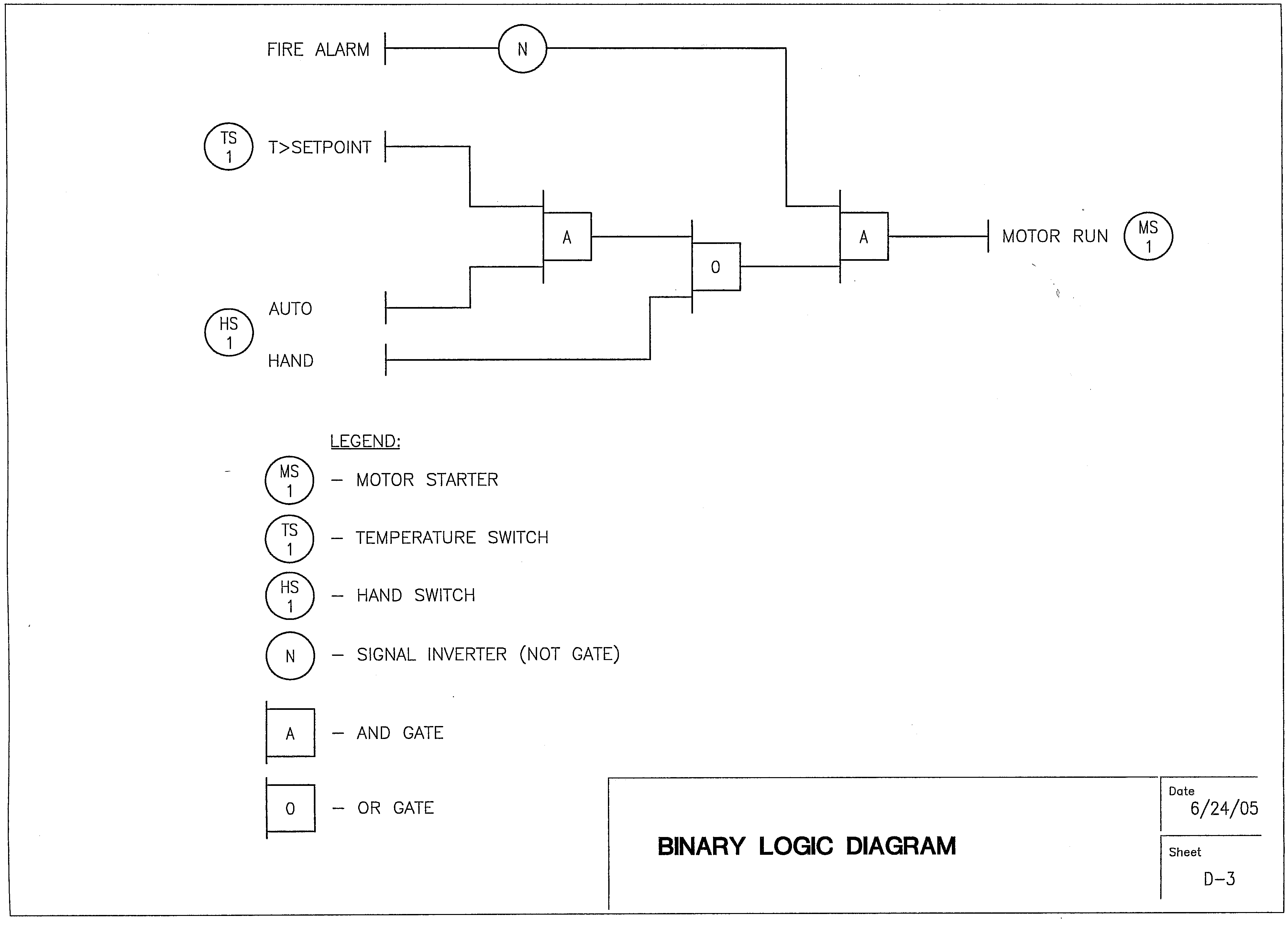

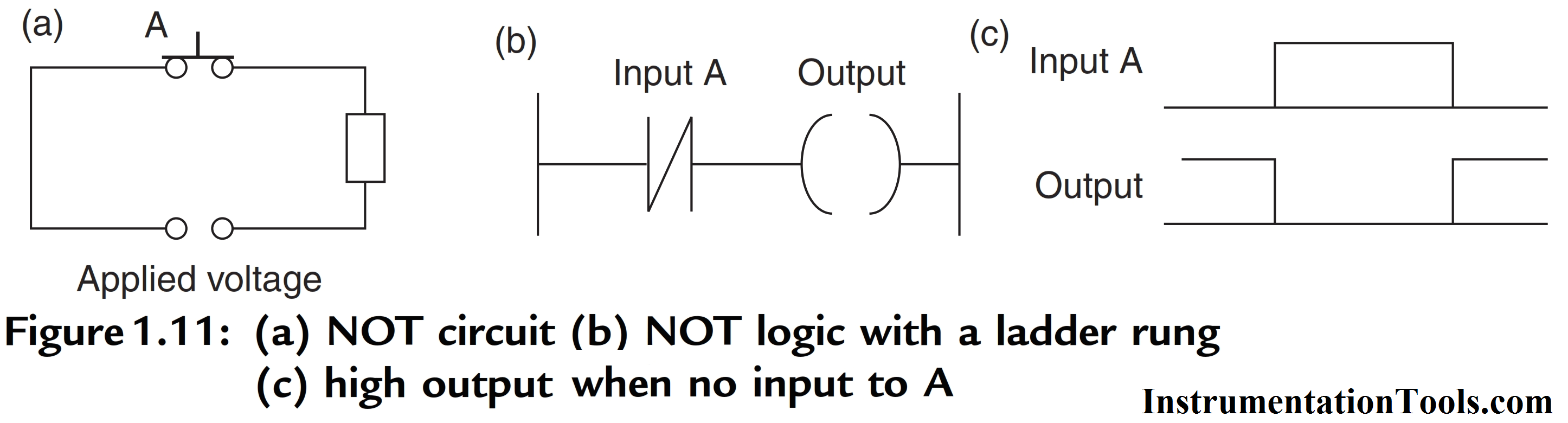

The first three are the inverter, and, as well as or. Enabling objectives 1.1 identify the symbols used on logic diagrams to represent the following components: Ladder diagram showing an inverter boolean logic structure.

1974 yamaha dt175 wiring schematic 4 wire o2 sensor diagram 2007 saab 9 5 headlight wiring diagram 96 accord wiring diagram

Documentation and Change Control of PLC or DCS Systems

High voltage switchgear 13 figure 6. Enabling objectives 1.1 identify the symbols used on logic diagrams to represent the following components: Logic sequence flow step charts. Circular symbol used to denote and identify the purpose of an instrument or function.

Source: instrumentationtools.com

Understand feedback, feedfoward, cascade and ratio control. Audit of p&id is to be done for proper indication of. Develop the logic diagram in such a way that it presents results in a positive logic format. The first three are the inverter, and, as well as or. It includes all piping, instruments, valves and equipment that the system consist of.

Source: instrumentationtools.com

It’s most commonly used in the engineering field. They shall be prepared from the following: It includes all piping, instruments, valves and equipment that the system consist of. Circular symbol used to denote and identify the purpose of an instrument or function. To be able to install and calibrate basic instruments.

Source: instrumentationtools.com

They show all the instruments in a control loop; The diagram contains graphic symbols that are interconnected to describe the logical relationships among different process equipment or calculated inputs and outputs. Instrument logic diagram for actuated valve, esd/psd, f&g, pump & fan motor, mcs, tcs instrument loop safety integrity level listing (sil). In oil and gas project, the production sequence.

Source: pinterest.com

Activities and logical sequence for electrical and instrumentation engineering. Typical information you would see on an instrument loop diagram or sheet are: And, therefore, is the only logical structure with only one input. • define and use process flow diagrams, p&id's, instrument lists, specification forms, logic diagrams, location plans, installation details and loop diagrams • understand process control devices and.

Source: instrumentationtools.com

Also known as basic regulatory controls. Continuous circuit 26 figure 11. The block diagram shown above is of basic instrumentation system. 3.2 a logic diagram may be more or less detailed depending on its intended use. Each instrument bubble in a loop diagram represent an individual device with its own terminals for connecting wires.

Source: instrumentationtools.com

Piping and instrumentation diagram, also called p&id, is a diagram used to show a graphical display of a complete system. They shall be prepared from the following: High voltage switchgear 13 figure 6. Digital ammeter 17 figure 7. Apply basic instrumentation to control an industrial process.

Source: instrumentationtools.com

They are used to depict monitoring and control loops in functional instrument diagrams, functional logic diagrams, application software diagrams, sketches, and text. These diagrams focus on the flow of information within a control system rather than on the process piping or instrument interconnections (wires, tubes, etc.). Understand feedback, feedfoward, cascade and ratio control. Enabling objectives 1.1 identify the symbols used.

Source: researchgate.net

Continuous circuit 26 figure 11. The following people served as members of isa committee sp5.1, which prepared this standard: E.g., a command to open Also known as basic regulatory controls. • define and use process flow diagrams, p&id's, instrument lists, specification forms, logic diagrams, location plans, installation details and loop diagrams • understand process control devices and the symbols used.

Source: pinterest.com

P&id shows all of piping including the physical sequence of branches, reducers, valves, equipment, instrumentation & control interlocks. Functional diagrams focus on the flow of information within a control system rather than on the process piping or instrument interconnections (wires, tubes, etc.). • define and use process flow diagrams, p&id's, instrument lists, specification forms, logic diagrams, location plans, installation details.

Source: instrumentationtools.com

Logic sequence flow step charts. Ladder diagram for a load device. Understand feedback, feedfoward, cascade and ratio control. A logic system may have two opposing inputs. Typical information you would see on an instrument loop diagram or sheet are:

Source: instrumentationtools.com

They are used to depict monitoring and control loops in functional instrument diagrams, functional logic diagrams, application software diagrams, sketches, and text. Simple ladder diagram 24 figure 8. The inverter simply causes a true input condition to create a false output condition; Basically transducers are used as a primary sensing element. Enabling objectives 1.1 identify the symbols used on logic.

Source: instrumentationtools.com

A) instrument line symbols b) instrument functional diagramming symbols c) mathematical function block symbols The primary sensing element is also known as sensor. These diagrams focus on the flow of information within a control system rather than on the process piping or instrument interconnections (wires, tubes, etc.). Three element drum level control Apply basic instrumentation to control an industrial process.

Source: instrumentationtools.com

It consist of primary sensing element, variable manipulation element, data transmission element and data presentation element. • define and use process flow diagrams, p&id's, instrument lists, specification forms, logic diagrams, location plans, installation details and loop diagrams • understand process control devices and the symbols used to define them • define and specify vendor criteria for the production of plant.

Source: instrumentationtools.com

The diagram contains graphic symbols that are interconnected to describe the logical relationships among different process equipment or calculated inputs and outputs. Audit of p&id is to be done for proper indication of. In oil and gas project, the production sequence of electrical and. Enabling objectives 1.1 identify the symbols used on logic diagrams to represent the following components: To.

Source: instrumentationtools.com

A) instrument line symbols b) instrument functional diagramming symbols c) mathematical function block symbols Ladder diagram showing an inverter boolean logic structure. Simple ladder diagram 24 figure 8. A piping & instrumentation diagram or p&id is a schematic illustration of the functional relationship of piping, instrumentation, and system equipment components. A piping and instrumentation diagram, or p&id, shows the piping.

Source: mouser.com

It includes all piping, instruments, valves and equipment that the system consist of. Basically transducers are used as a primary sensing element. Through a p&id, you can get the following information: A piping and instrumentation diagram, or p&id, shows the piping and related components of a physical process flow. Sample circuit 25 figure 9.

Source: instrumentationtools.com

Apply basic instrumentation to control an industrial process. They shall be prepared from the following: Ladder diagram for a load device. (see also hlcs and sis) bubble: Piping and instrumentation diagram, also called p&id, is a diagram used to show a graphical display of a complete system.

Source: instrumentationtools.com

The block diagram shown above is of basic instrumentation system. The primary sensing element is also known as sensor. Circuit diagram 5 figure 3. Audit of p&id is to be done for proper indication of. Apply basic instrumentation to control an industrial process.

Source: instrumentationtools.com

Apply basic instrumentation to control an industrial process. The primary sensing element is also known as sensor. Logic sequence flow step charts. Audit of p&id is to be done for proper indication of. It consist of primary sensing element, variable manipulation element, data transmission element and data presentation element.

Source: pinterest.com

Read p&ids (process and instrumentation diagrams). Understand feedback, feedfoward, cascade and ratio control. Three element drum level control Continuous circuit 26 figure 11. (see also hlcs and sis) bubble: